Switch on to Envorem with Pawel Wieczorek, our Senior Controls and Electrical Engineer

From a single cable to the brain of our Envorem system, Pawel Wieczorek makes everything interwork. This could be on an installation in the UK or in the Middle East. As our Senior Controls and Electrical Engineer, he is the conductor ensuring that our complex orchestra of sub-systems are integrated and operating in harmony.

All Pawel is waiting for, is for more major oil producers to switch on to the Envorem Sludge Remediation System as an ideal solution to the by-products of oil production. This will initiate a fleet of clean-up plants across the globe.

Pawel has also been part of an innovative R&D project to automatically measure sand sediment in multiphase tanks. Envorem News caught up with him on Zoom while he was working from home.

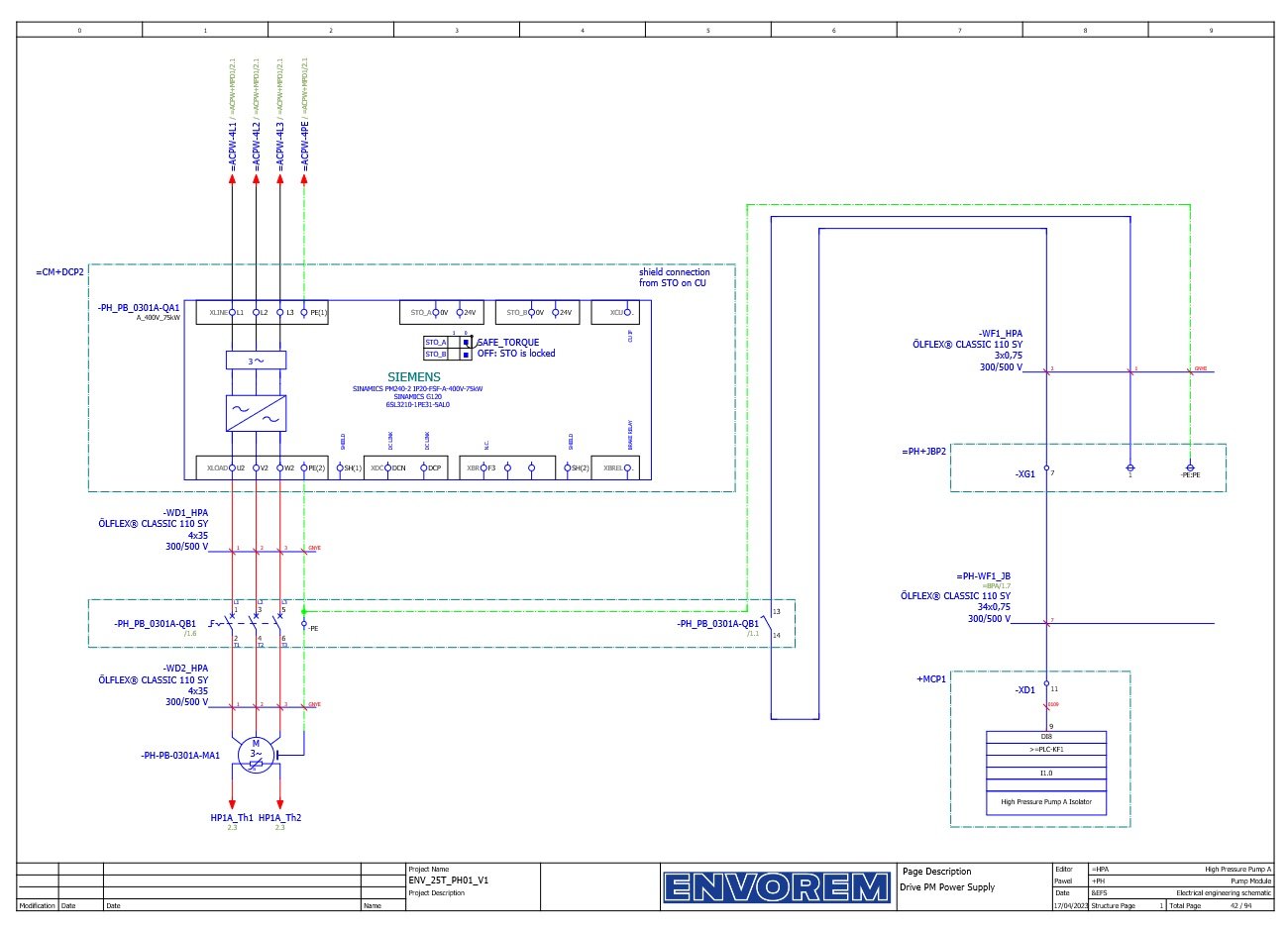

Pawel Wieczorek has been at Envorem for close on two years. He lives near Oxford, along with his wife and two children. His daughter (11) and son (5) don’t think he has a job because he spends the whole day drawing! That is partially true, Pawel can invariably be found working on EPLAN and Solid Edge, the PLM software from Siemens that has been used to design the Envorem System. However, there is much more to his job than that as we will find out.

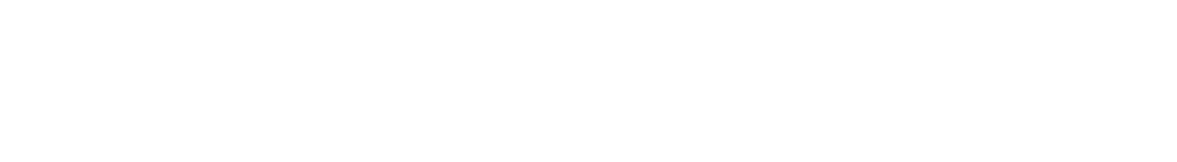

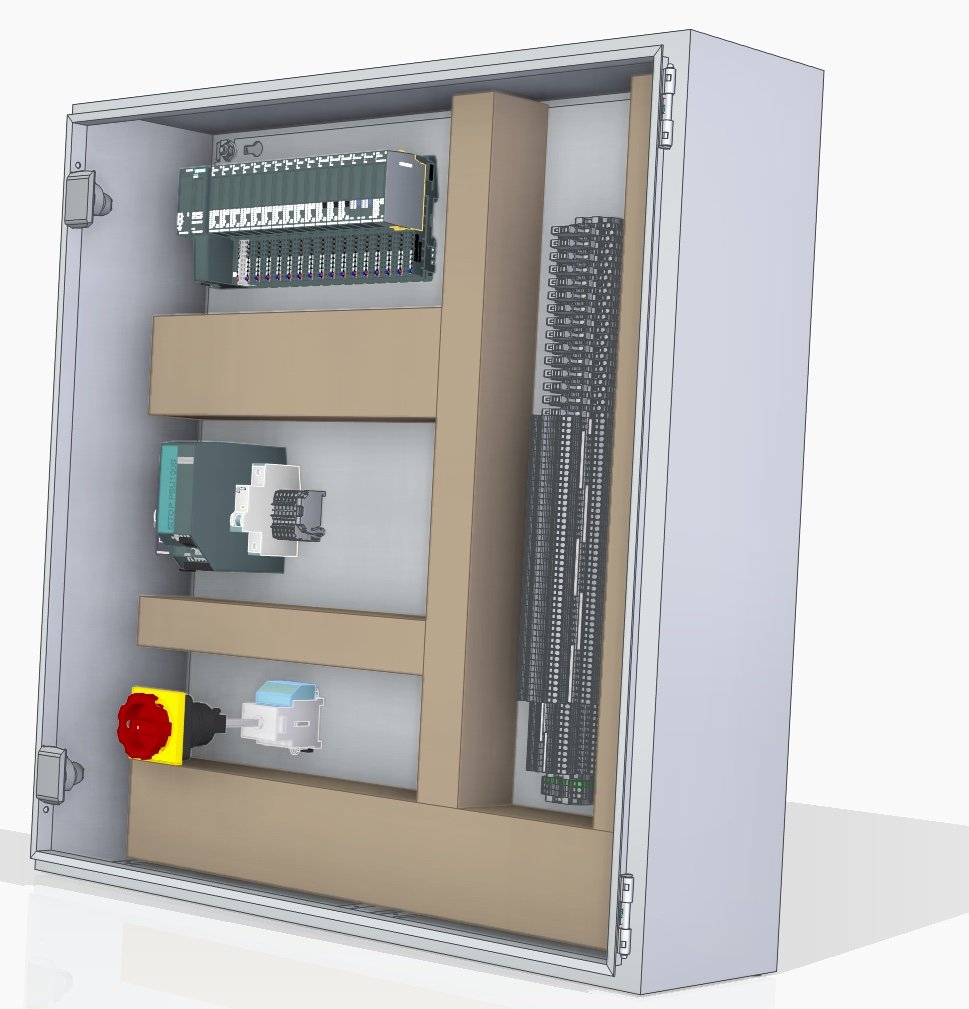

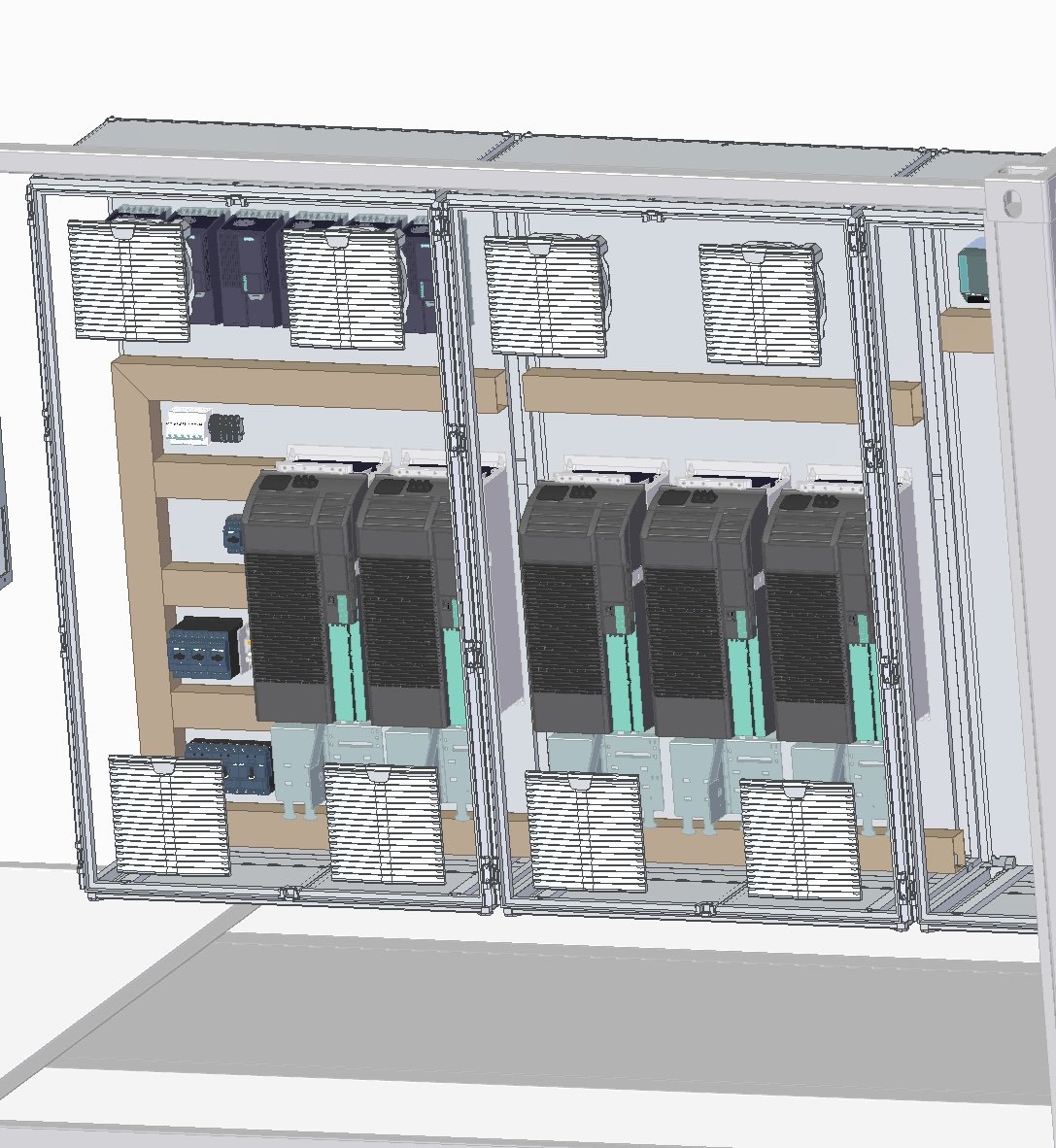

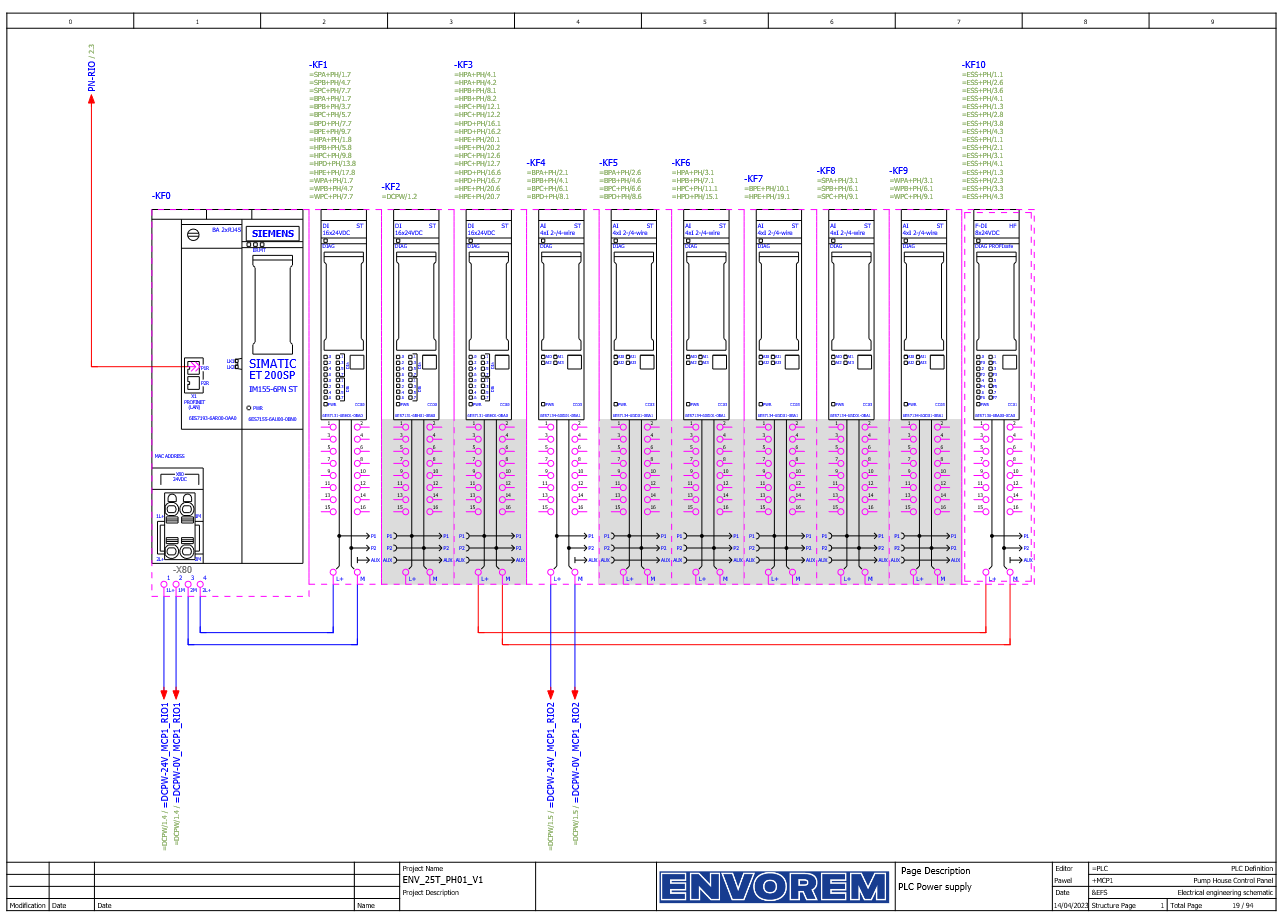

Pawel works with the Envorem team of designers headed by Ben Monkton bringing his area of expertise. “I am responsible for designing the controls and electrical side of the Envorem System from the beginning,” he says. “I devise the control philosophy and select the appropriate electrical components. That, could be VSD (Variable Speed Drive), fuse, PLC cards, instrumentation etc. I handle everything from a single cable to the brain of the system.”

So, what kind of qualifications did Pawel need to deal with such complexity? “It’s a long list,” he says. “Firstly, I attended technical college in Poland where I learnt to design electronic projects from scratch. It's kind of woven into the fabric of who I am! Then, after college I got a job as a Senior Electronic Technician before moving up to Maintenance Engineer to Service Engineer and Project Manager to where I am today.”

Before coming to Envorem, Pawel worked as an Automation Engineer for Technique Services International Limited for several years, an electrical, and electronics repair firm based in Manchester. He joined Envorem on 1 December 2021 and flew out to Oman on 5 December to visit our Pilot Project. He has travelled to Oman several times since then and regularly travels to Envorem HQ in Stoke-on-Trent.

”Pawel is a fantastic asset to the team,” says Envorem Managing Director, Mark Batt-Rawden. “He has always enjoyed electrical engineering and it has been a source of focus from his early childhood. He has worked on an array of work in the field of electrical engineering, from pure electronics design to electrical designs, maintenance, installations, software development and all the way to project management. I love his ‘can do’ attitude and willingness to muck in whatever the challenge.”

Why work for a green tech company?

“Concerns for the environment have always been there, at the back of my mind,” Pawel says. “It’s important to give something back to the place we live and certainly we have been careful to recycle as a family, but with Envorem came the opportunity to be part of making a much bigger impact! It is good to work with a company that actually cares about the future of our planet.”

Talking about the new Envorem Headquarters in Newstead Industrial Estate in Stoke-on-Trent, Pawel outlines the facility’s two-fold purpose. Firstly its a place where we are building our entire system, to be completed in Autumn, and secondly it is where we test new technologies aimed at providing greener alternatives.

The Envorem Sludge Remediation System comprises several containers all linked together with the machinery in place to rapidly and inexpensively process oil production sludges. As Remediation Technology puts it, “This amazing technology, uses very little energy to disassemble sludges, clean the solids and recover the entrained oil for recycling - all without using chemicals or generating emissions.”

“In addition to our field trials in Oman, we have tested many samples in Stoke from around the world and had good results,” says Pawel. “We can also test the remediation of waste materials other than sludge. This is because the system is so modular. All we need to do is alter how we feed stock into the system. With this small change we can treat other materials for example, toxic coal tar. The beauty of our system is that it can easily adapt to treat various forms of waste that pollute our environment.

“With time, we would love to tackle things like Agent Orange pollution in Vietnam and the masses of oily millscale from steel production.”

Pawel Wieczorek on R&D

The Envorem Sludge Remediation System has taken significant research and development and is constantly being refined. Pawel is pleased to have played a role in the R&D phase of the project.

”The team environment at Envorem is so motivating. We are pushing the performance boundaries of many different technologies and the whole team gets involved in problem solving. Our favourite space is our large conference table flanked by massive whiteboards on the walls. Our creative sessions in Stoke are both productive and fun.”

One of the facets of the system Pawel is most pleased with is an electronic measuring system for sediment levels that he has contributed to. The problem is detecting accurately the dynamic level of sediment in a tank containing phases of oil, water and sediment.

”Ben, Mark, Mike and I were having a whiteboard session and we devised a new concept using maths, electricity and a computer,” Pawel explains. “I ran a test in my kitchen to see if it would work and it did! We then ran other tests on a bigger scale. The idea certainly proved successful on location in Oman, and we are now going to test it on the main system in Stoke.”

“There was nothing on the market that could achieve this, so we came up with our own design. Now we have to test it and improve it, and I am sure it will be part of the final Envorem system. This was all pure R&D and it worked! We have since filed a patent for the technique.”

Looking at these technical blueprints, which give us a glimpse into the electrical engineering Pawel does, and his keenness to serve the environment, it’s clear he’s is not just drawing pretty pictures as his son and daughter think, but creating a brighter future for his children.